Unprecedented part performance

3D printed parts oftentimes suffer from strong anisotropy, mainly due to weak bonds between the layers. Our DEMEX system uses continuous spectrum light to heat the substrate just before the nozzle, which allows the material to form a complete bond. The result is isotropic, high mechanical part performance that is achieved repeatedly and reliably, which enables completely new possibilities for additive manufacturing.

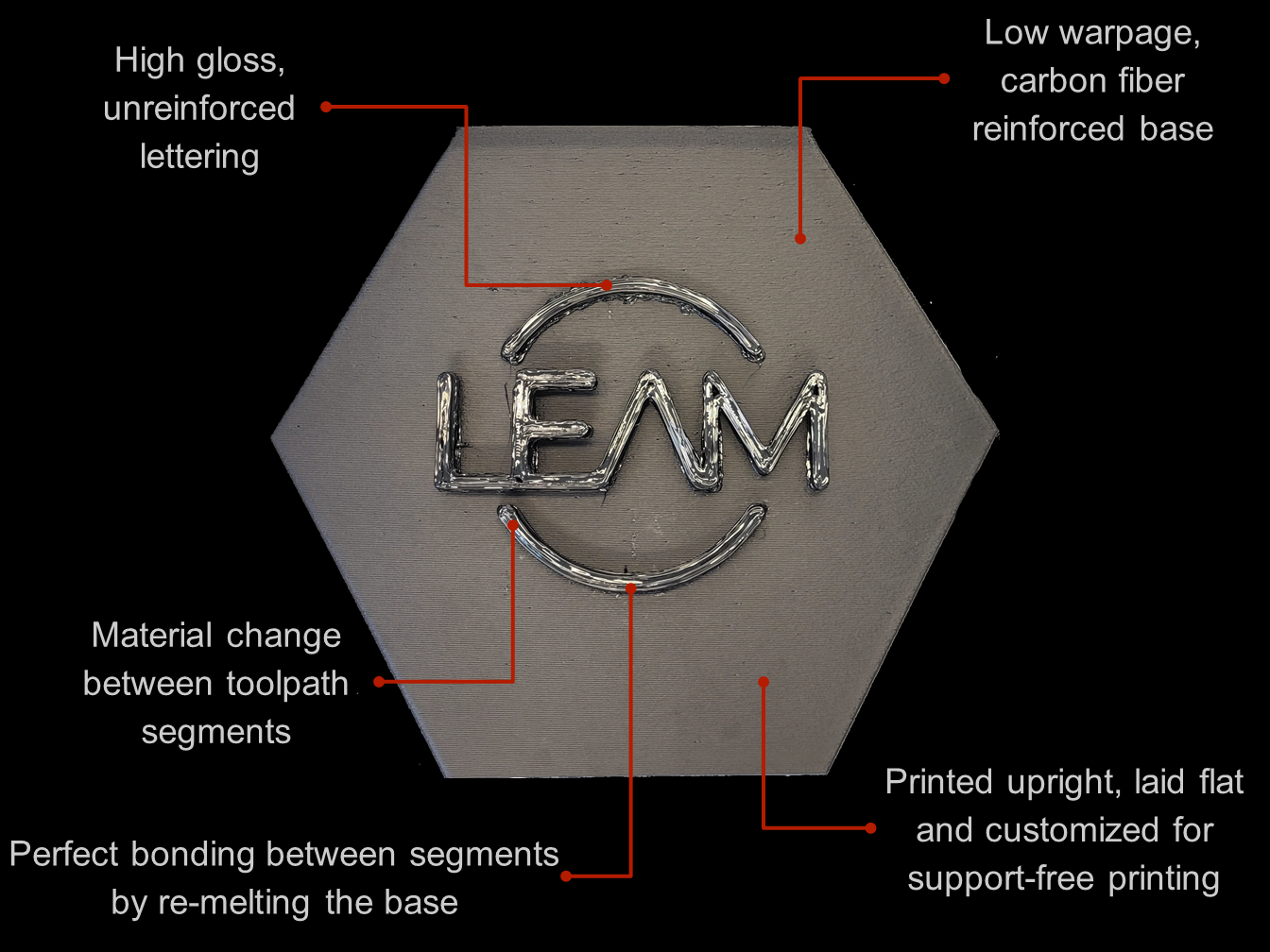

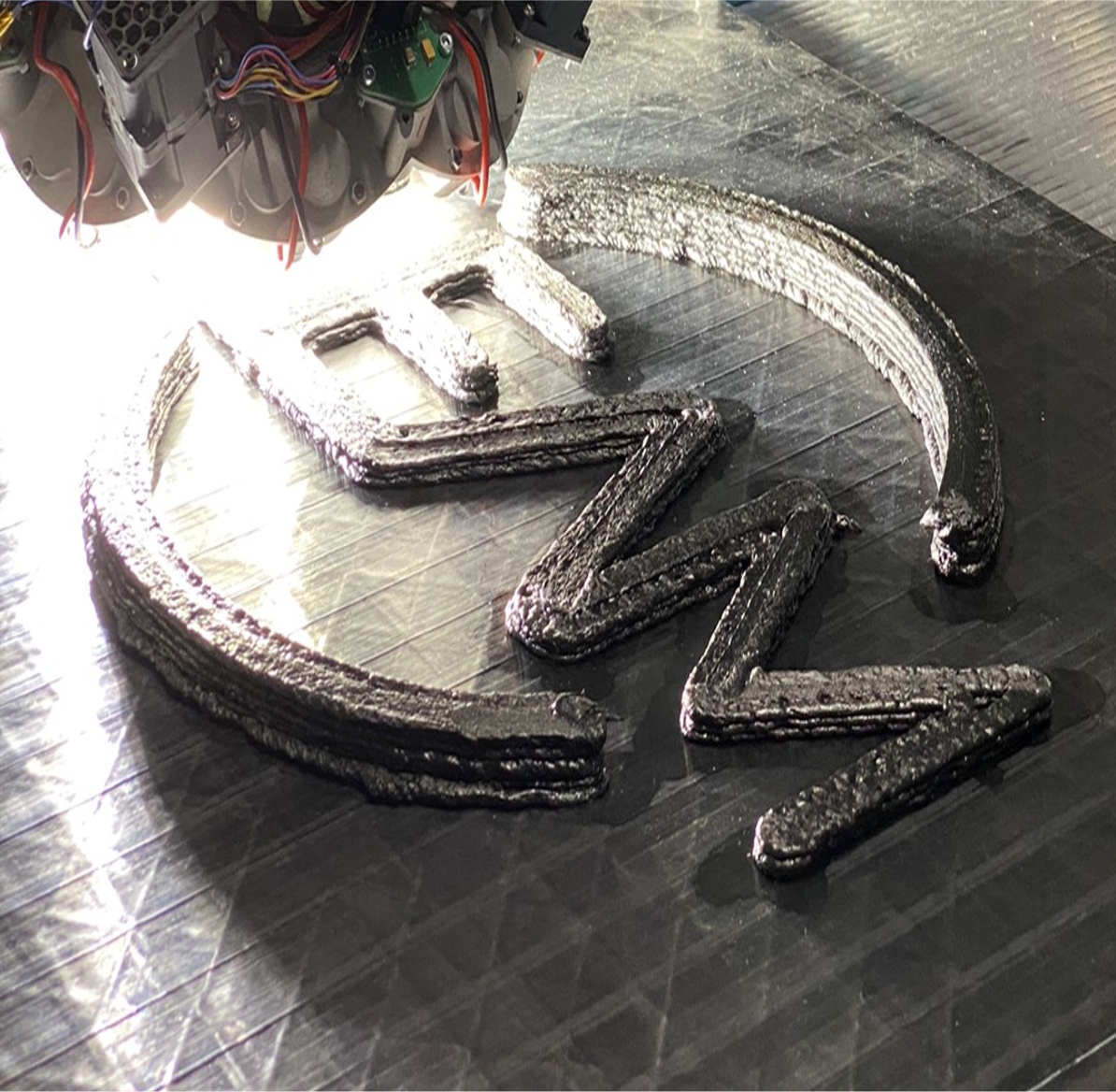

New process combinations

With our system you can functionalize and individualize parts that are manufactured in another process, such as injection molding. It also allows you to print parts from one material, interrupt the printing process for material change, and add further elements to the part in another material. With DEMEX it becomes possible to print on cold surfaces and still achieve perfect bonding. You can have the right material at the right spot.

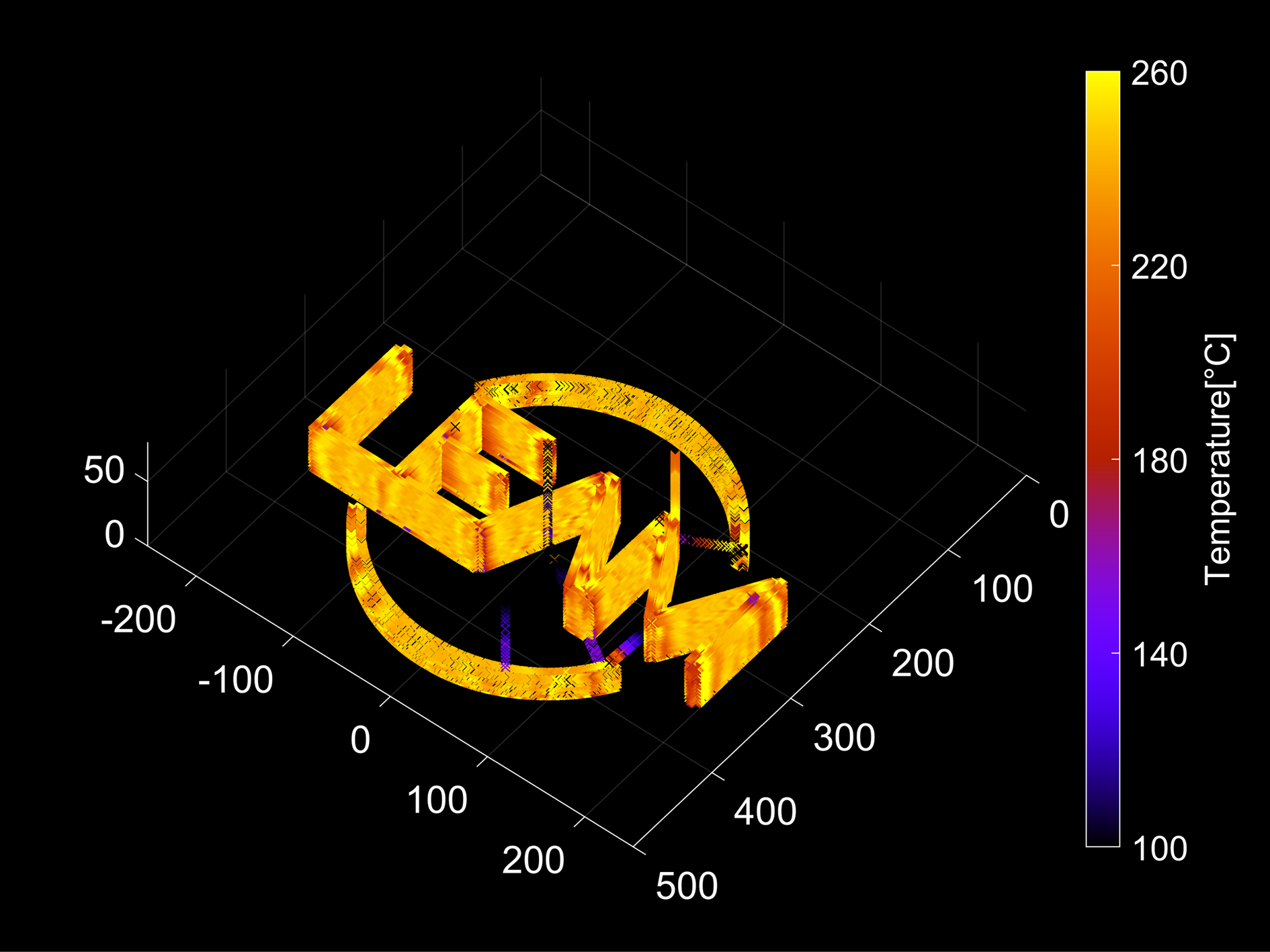

Digital twin

Parts used in demanding sectors such as aerospace or oil & gas must satisfy the specified mechanical performance and durability. For this purpose, it is necessary to keep track of every detail of the production process. With our systems you can generate a digital twin of your parts. In addition to all relevant machine parameters, the bonding temperature at every position in the part is recorded. This enables the complete and continuous documentation, like a birth certificate for the part, without additional effort for the manufacturer.

Copyright © 2024 LEAM Technologies GmbH