Temperature Monitoring

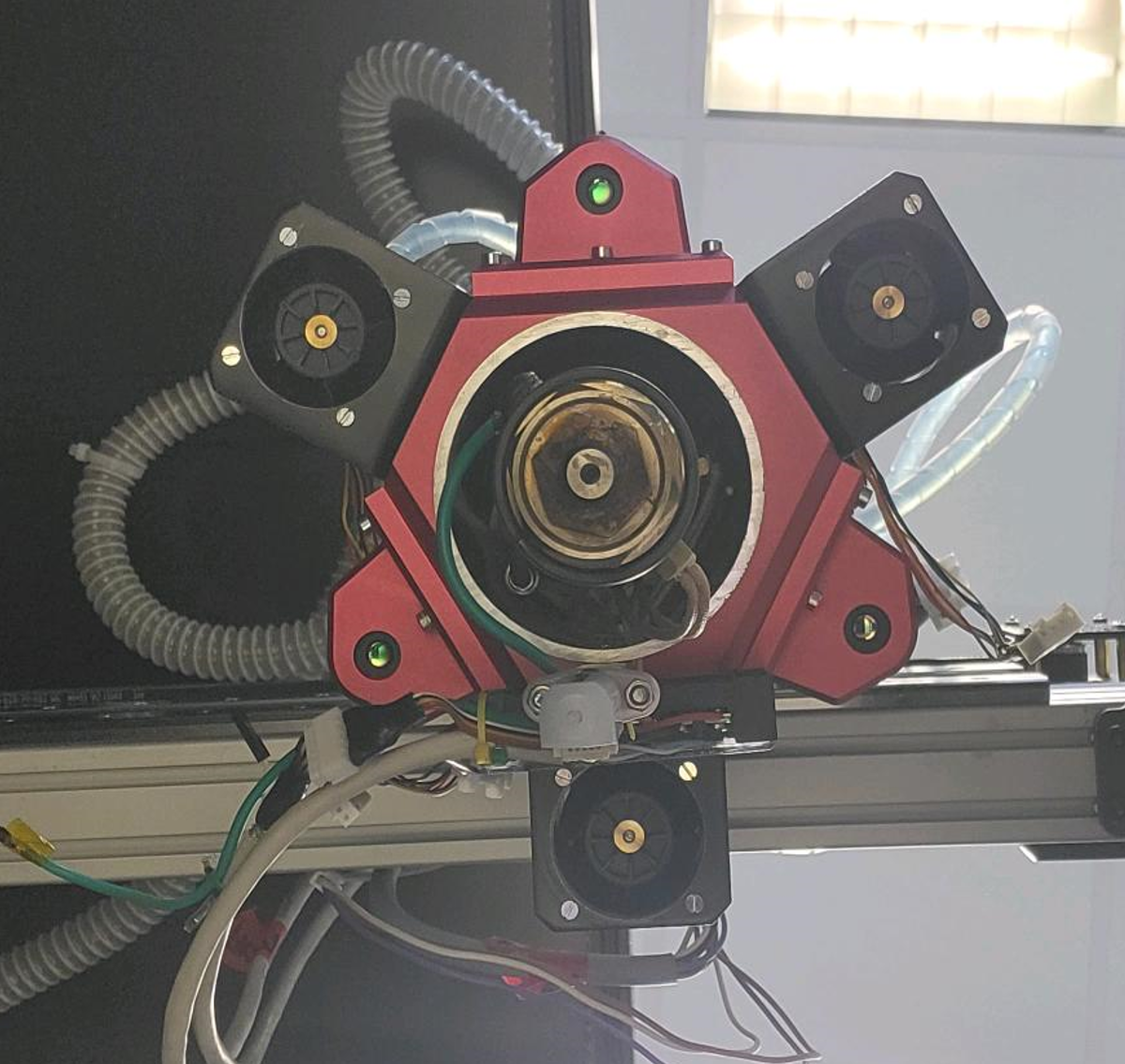

The temperature of the part during printing is crucial to ensure stable printing conditions. For this purpose, LEAM developed the Temperature Monitoring system.

The Temperature Monitoring system is an add-on that can be installed on any large-scale 3D printer. It detects the temperature of the printed part and continuously informs the user about the current conditions.

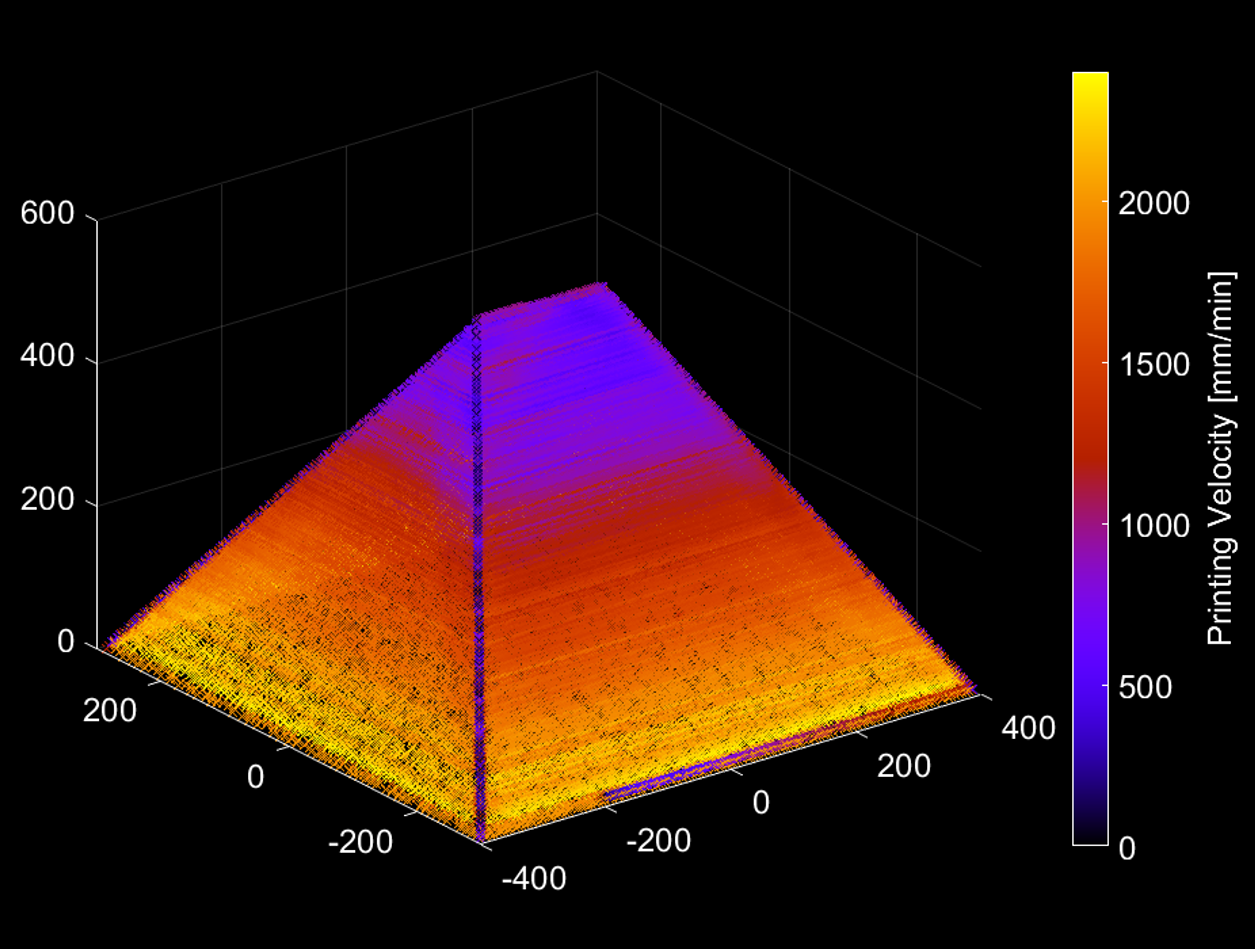

A feedback loop to the printer enables completely new possibilities in terms of reliability and print quality. An overheating part is detected early, active cooling can be activated, or the print speed can be reduced accordingly to save the print job. This allows the machine to always print as fast as possible saving time and money.

Time-consuming temperature simulations before printing are not needed. The user can start the job and let the system regulate itself. The Temperature Monitoring system works independently and due to its 360° coverage, you don't need to worry about it during slicing.

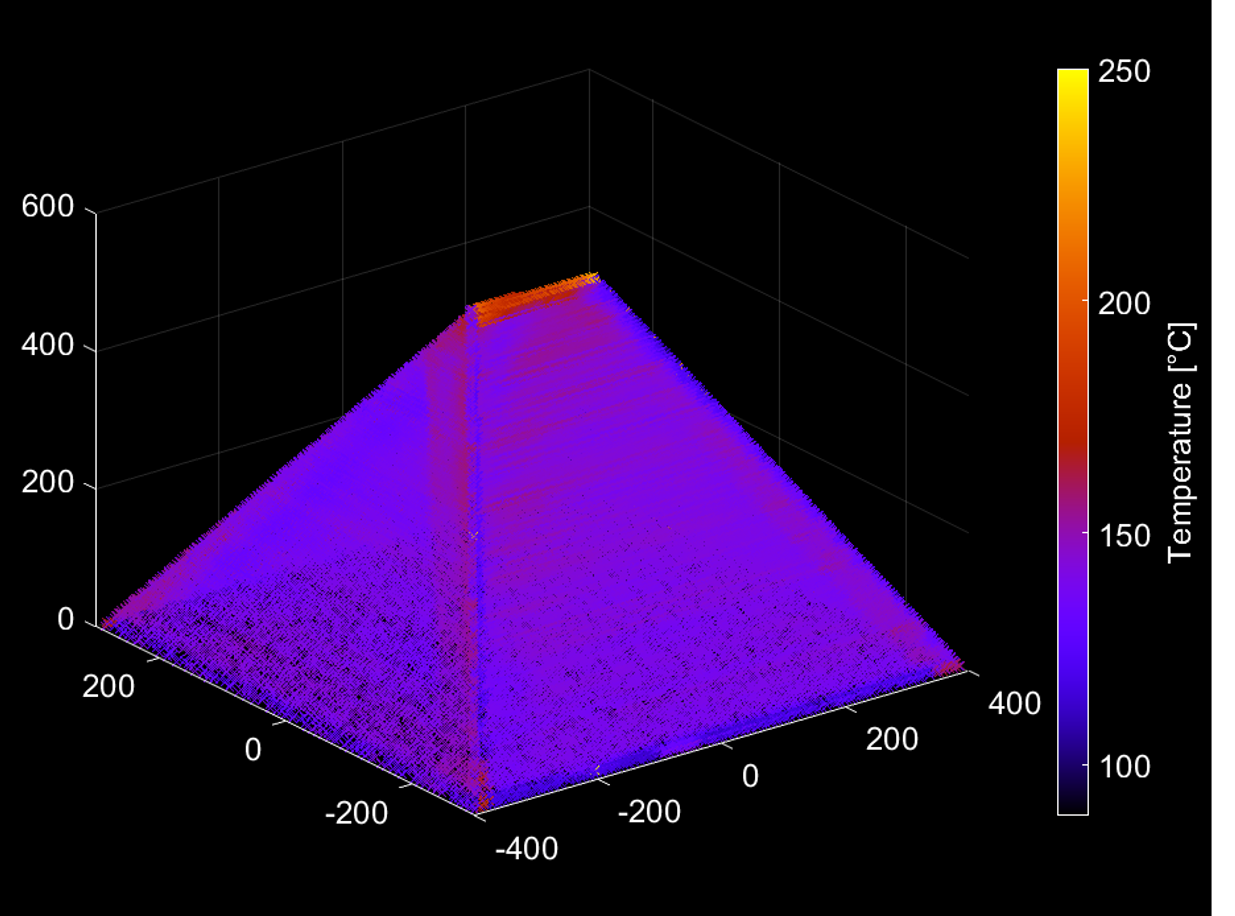

The monitored temperatures as well as desired machine parameters are logged to generate a digital twin of every part. With this at hand, a manufacturer can reconstruct every detail of a print job and prove the correct production conditions. This data acts like a birth certificate that can be associated to the part over its entire service life.

Recorded substrate temperature

Recorded printing speed

LEAM's Temperature Monitoring system allows you to:

- Print up to 50% faster than before saving time and money

- Be sure that the printed parts never overheat since the manufacturing machine automatically counteracts if needed

- Generate a digital twin of every part including bonding temperatures and all desired machine parameters

Copyright © 2024 LEAM Technologies GmbH