DEMEX

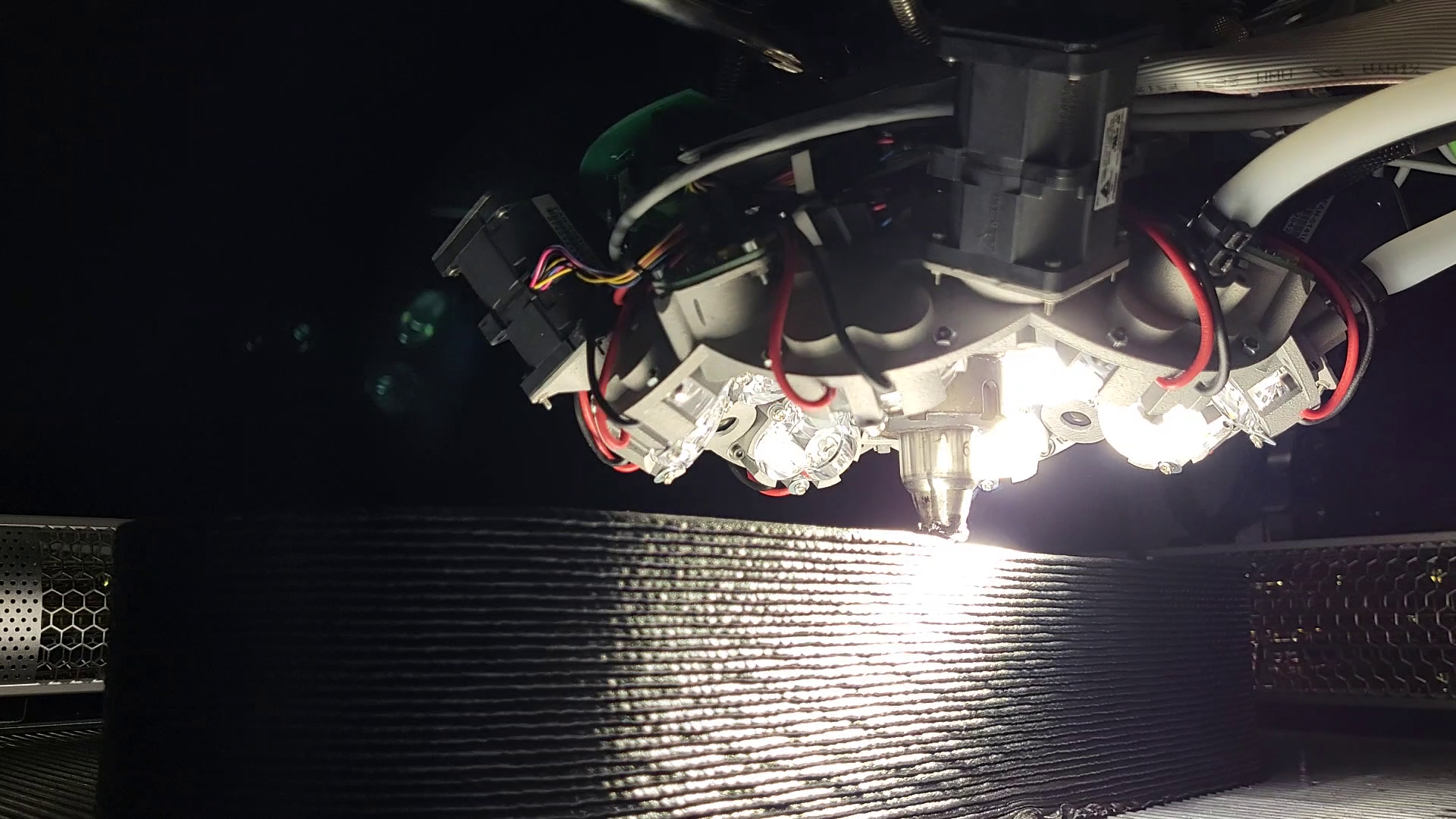

We developed a technology we are calling "DEMEX“, short for Directed Energy Material Extrusion. The system is an add-on that can easily be integrated into any large-scale 3D printer.

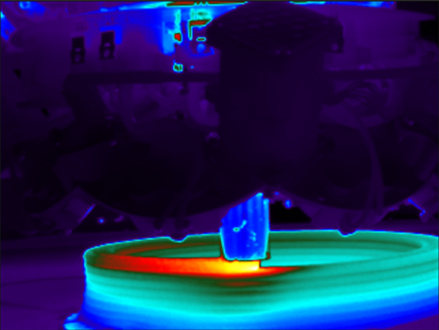

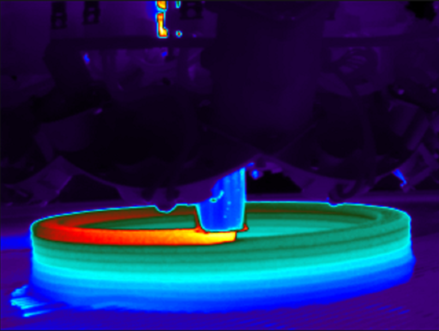

Using continuous spectrum light to heat the material just before the nozzle, DEMEX welds the layers together. This results in unprecedented mechanical performance, even with tough to print materials, like semi-crystalline injection molding grades. And because it's not a laser, it's safe and easy to integrate.

The system monitors and locally re-melts the material, without compromising the overall stability of the print. It has 360° coverage, so you don't need to worry about orientating it during slicing.

The DEMEX system opens up new possibilities for the user and enables applications that have so far not been feasible for additive manufacturing. You can now:

- Print parts with isotropic strength and stiffness - No weak spots between the layers

- Print with injection molding grades - Take advantage of proven & lower-cost materials in your application.

- Combine multiple materials in one print - The right material in the right place, even with a single extruder.

- Manufacture parts with new process combinations - Functionalize and individualize CFRP components or injection molded parts.

- Interrupt the process if needed - Stop after a production shift, restart the next day where you left off.

Heaters on

Heaters off

Copyright © 2024 LEAM Technologies GmbH